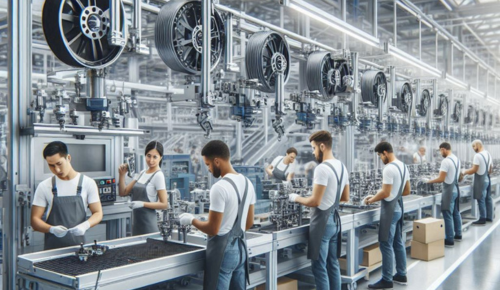

A flywheel manufacturer doesn’t just shape a part, they bring engineering knowledge and experience to every stage. This expertise ensures that the flywheel has the right balance, improving both safety and the performance of the vehicle. The meticulousness of the manufacturer is reflected in every detail, from the quality of the materials used to the precision of the production process. A good flywheel improves the driving dynamics of the vehicle, while at the same time increasing the efficiency of the engine. The role of the flywheel manufacturer is therefore an art that requires not only technical knowledge, but also experience and care.

Flywheel Gear

There are indispensable materials and spare parts in vehicles and automobiles. In this context, spare parts materials, which are categorized among themselves, allow vehicles and automobiles to drive much more beautifully. The most striking spare parts materials in vehicles and automobiles are the material called flywheel gear.

This product also draws attention as a material that tolerates the engine movement mechanism. In order to get detailed information about the product, vehicle owners can reach all the details by doing research. In this context, the flywheel reflects a large gear system that sends the first movement to the vehicle’s engine.

This gear takes its power from the starter dynamo, and the starter dynamo works when the starter is pressed when the vehicle is first started. The starter dynamo gear system transfers the rotational force from the starter motor to the flywheel gear.

What is a Flywheel Gear in Vehicles?

While millions of cars and automobiles continue to cruise in traffic, there are brand new developments related to vehicles and automobiles. In this context, there are various spare parts and materials that are remarkable in vehicles and offer a very nice use.

Among such spare parts and materials is the product called flywheel gear. This product also serves as a system that transmits the first movement mechanism to the vehicle. This system constitutes the indispensable by-product materials in all vehicles and automobiles.

The flywheel gear, which has a quality working principle, also carries a large gear system that sends the first movement to the vehicle’s engine. Without such a spare part, the vehicle cannot move at all. This gear system constitutes the most remarkable spare parts and materials in vehicles and automobiles.

Flywheel Gear Mechanism

Vehicles and automobiles are among the most basic needs for convenient and comfortable transportation. Vehicles sweep users off their feet, so to speak. In this context, a number of side materials and equipment are needed in the production of vehicles.

Among such equipment is the flywheel gear mechanism. Thanks to such a mechanism, the first movement is transferred to the vehicle through gears. In this way, the vehicle does not cause any problems or problems when taking off.

Although those who do not have information about this subject do research in curiosity, the gear that provides the movement mechanism is recorded as the flywheel gear.

What is a Flywheel Gear and What Does It Do?

Millions of vehicle brands are available for all vehicle enthusiasts. Such vehicles also reveal options that are produced in detail. The most striking parts and materials in vehicles and automobiles are the flywheel gear.

In this context, research is also being done on questions such as what is a flywheel gear and what does it do. To summarize this issue briefly, the answer that the material called the flywheel gear provides the gear duty that gives the first movement of the vehicle emerges.

Flywheel and Flywheel Gear Maintenance

Without regular maintenance, a flywheel gear can wear over time, leading to loss of performance, erratic operation and even serious mechanical failure. When minor wear goes unnoticed, gears become more difficult to repair, increasing costs in the long run. Lack of lubrication or accumulation of dirt makes it difficult for the gear to move, preventing the system from working efficiently. This can disrupt the overall balance of the machine, causing vibration and noise.

Excessive friction and irregular movement leads to increased strain on the motor or connected components. As a result, the life of the machine is shortened and unexpected breakdowns can occur. Especially in high-power machines, such problems directly affect productivity. Regular checks and timely interventions protect the workflow by preventing sudden stops.

An unmaintained gear can negatively affect not only its own performance, but all connected systems. Overheating and irregular power transmission cause mechanical parts to wear out faster. Therefore, checking the flywheel gear at regular intervals is one of the most important steps to ensure efficient and safe operation of the machine.