In today’s industrial landscape, the efficient handling of gases and liquids is crucial. Oil vacuum pumps, particularly the rotary vane vacuum pump, have emerged as indispensable tools in various applications. Whether you’re a seasoned engineer or just curious about the world of vacuum technology, this article will provide you with a comprehensive understanding of oil Vacuum Pumps, with a special focus on the rotary vane vacuum pump.

1. Introduction

Oil vacuum pumps play a pivotal role in diverse industries, from manufacturing and healthcare to research and food processing. These pumps create and maintain a vacuum within a closed system, enabling the efficient transfer of gases and liquids. Among the various types of vacuum pumps, the rotary vane vacuum pump stands out for its reliability and versatility.

2. What is a Vacuum Pump?

A vacuum pump is a mechanical device designed to remove air, gases, or vapors from an enclosed space, creating a vacuum. This process has numerous industrial, scientific, and commercial applications.

3. Types of Vacuum Pumps

There are three main categories of vacuum pumps:

3.1 Positive Displacement Pumps

Positive displacement pumps physically capture and remove gas molecules from the system. Rotary vane vacuum pumps fall under this category.

3.2 Momentum Transfer Pumps

Momentum transfer pumps use high-speed jets or rotating blades to transfer gas molecules from one side to another.

3.3 Entrapment Pumps

Entrapment pumps trap gas molecules in a solid or adsorbent material.

4. The Role of Oil in Vacuum Pumps

Oil is a crucial component in many vacuum pumps, including rotary vane vacuum pumps. It serves multiple purposes, such as sealing, lubricating, and cooling the pump’s components.

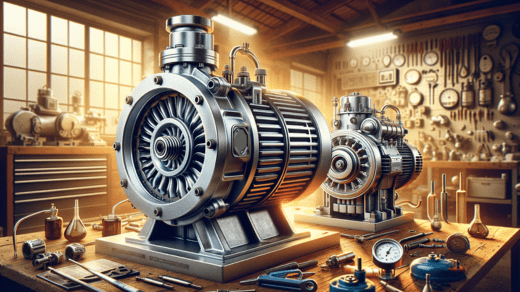

5. Anatomy of a Rotary Vane Vacuum Pump

To understand how a rotary vane vacuum pump operates, let’s dissect its structure:

5.1 Housing

The pump’s housing encases all the internal components, providing a sealed environment.

5.2 Rotor

The rotor is a central rotating component within the pump.

5.3 Vanes

Van…es are typically made of a durable material like carbon or plastic. They are attached to the rotor and slide in and out of slots within the housing, creating a seal as they move.

5.4 Inlet and Outlet Ports

The inlet port is where the pump draws gas from the system, while the outlet port expels the gas into the desired container or exhaust system.

6. How Does a Rotary Vane Vacuum Pump Work?

Understanding the operation of a rotary vane vacuum pump is essential for appreciating its efficiency. As the rotor turns, the vanes slide in and out, maintaining contact with the inner surface of the housing. This action creates expanding and contracting volumes within the pump. When the volume increases, air is drawn in through the inlet port. As the volume decreases, the air is compressed and expelled through the outlet port.

7. Advantages of Rotary Vane Vacuum Pumps

Rotary vane vacuum pumps offer several advantages:

- Reliability: They are known for their long service life and minimal maintenance requirements.

- Quiet Operation: These pumps operate with minimal noise levels, making them suitable for various environments.

- Versatility: Rotary vane vacuum pumps can handle a wide range of applications, from laboratory use to industrial processes.

- Efficiency: They provide consistent vacuum levels and high pumping speeds.

8. Applications of Rotary Vane Vacuum Pumps

The versatility of rotary vane vacuum pumps makes them indispensable in various industries:

- Laboratory Research: Used for sample preparation, solvent evaporation, and filtration.

- Medical: Employed in medical devices like blood analyzers and dental equipment.

- Manufacturing: Used in vacuum packaging, plastic molding, and vacuum coating.

- Food Processing: Essential for vacuum packaging and freeze-drying processes.

- Environmental Monitoring: Utilized in gas analysis and air quality monitoring equipment.

9. Maintenance and Care Tips

To ensure the longevity and performance of your rotary vane vacuum pump, follow these maintenance tips:

- Regularly change the pump oil as recommended by the manufacturer.

- Clean and inspect the pump’s components for wear and tear.

- Check for oil leaks and address them promptly.

- Keep the pump’s intake clean and free from debris.

10. Troubleshooting Common Issues

Rotary vane vacuum pumps may encounter issues such as reduced pumping speed or oil contamination. Consult your pump’s manual for specific troubleshooting steps and consider seeking professional assistance if needed.

11. Environmental Considerations

Properly disposing of used pump oil and adhering to environmental regulations is essential. Many vacuum pump manufacturers offer oil recycling programs to minimize environmental impact.

12. The Future of Vacuum Pump Technology

As technology advances, vacuum pump designs may become more efficient and environmentally friendly. Researchers are continually working to improve pump performance while reducing energy consumption.

In conclusion, oil vacuum pumps, particularly the rotary vane vacuum pump, are essential tools in a wide range of industries. Their reliability, efficiency, and versatility make them indispensable for creating and maintaining vacuums in various applications.