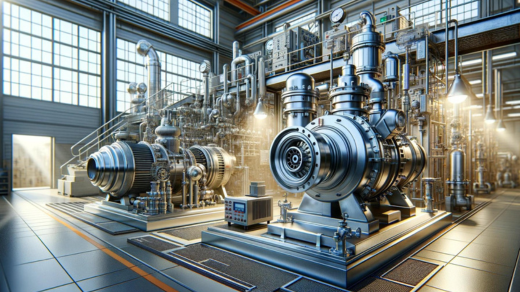

Side channel vacuum pumps are essential equipment in various industries and applications where vacuum generation is required. They operate based on the principle of centrifugal force and are known for their efficiency and reliability.

How Side Channel Vacuum Pump Works

Understanding the principle

Side channel vacuum pumps work by utilizing centrifugal force to create a vacuum. As the impeller rotates, it draws in air or gas through the inlet port. The rotating impeller then accelerates the air or gas and pushes it outward into the side channel, where it gains velocity and pressure. This continuous process creates a vacuum effect, effectively pulling air or gas from the system.

Components of a side channel vacuum pump

A typical side channel vacuum pump consists of an impeller, side channel, inlet and outlet ports, and a motor. The impeller is the rotating component responsible for creating the vacuum, while the side channel provides the necessary path for the air or gas to be expelled.

Applications of Side Channel Vacuum Pump

Side channel vacuum pumps find applications in industries such as packaging, printing, environmental technology, and more. They are used for tasks like vacuum conveying, drying, and packaging.

Advantages of Side Channel Vacuum Pump

- High efficiency

- Compact size

- Low noise operation

- Minimal maintenance requirements

Limitations of Side Channel Vacuum Pump

- Limited vacuum levels

- Sensitivity to dust and debris

Importance of Dry Vacuum Pump

Dry vacuum pumps play a crucial role in various industrial processes where oil contamination is undesirable. Unlike oil-sealed vacuum pumps, Dry Vacuum Pump do not require lubrication, making them suitable for sensitive applications.

How Dry Vacuum Pump Differs from Other Types

Dry vacuum pumps differ from other types of vacuum pumps, such as rotary vane pumps and liquid ring pumps, by eliminating the need for oil lubrication. Instead, they rely on mechanisms like screw or claw technology to create a vacuum without introducing oil into the system.

Working Principle of a Dry Vacuum Pump

Dry vacuum pumps utilize mechanisms such as screw or claw technology to create a vacuum without the need for oil lubrication. These pumps rely on the movement of screws or claws to compress and transfer air or gas from the inlet to the outlet, effectively generating a vacuum.

Applications of Dry Vacuum Pump

Dry vacuum pumps are commonly used in industries such as semiconductor manufacturing, pharmaceuticals, and food processing, where oil contamination is a concern. They are suitable for processes like vacuum drying, distillation, and degassing.

Advantages of Dry Vacuum Pump

- Oil-free operation

- Reduced risk of contamination

- Lower maintenance requirements

- Higher vacuum levels compared to side channel vacuum pumps

Limitations of Dry Vacuum Pump

- Higher initial cost

- Reduced efficiency at higher vacuum levels

Choosing the Right Vacuum Pump for Your Application

When selecting a vacuum pump for your application, consider factors such as required vacuum level, operating environment, maintenance requirements, and budget constraints. Assessing these factors will help you choose between a side channel vacuum pump and a dry vacuum pump.

Maintenance Tips for Vacuum Pumps

- Regularly inspect and clean inlet and outlet ports

- Check for signs of wear and tear on impeller blades

- Monitor motor performance and lubrication levels (if applicable)

- Follow manufacturer’s guidelines for maintenance and servicing

Side channel vacuum pumps and dry vacuum pumps are both essential tools for various industrial processes requiring vacuum generation. While side channel vacuum pumps offer compactness and efficiency, dry vacuum pumps provide oil-free operation and higher vacuum levels. Choosing the right vacuum pump depends on factors such as application requirements, environmental conditions, and budget considerations.